Electronic Assembly

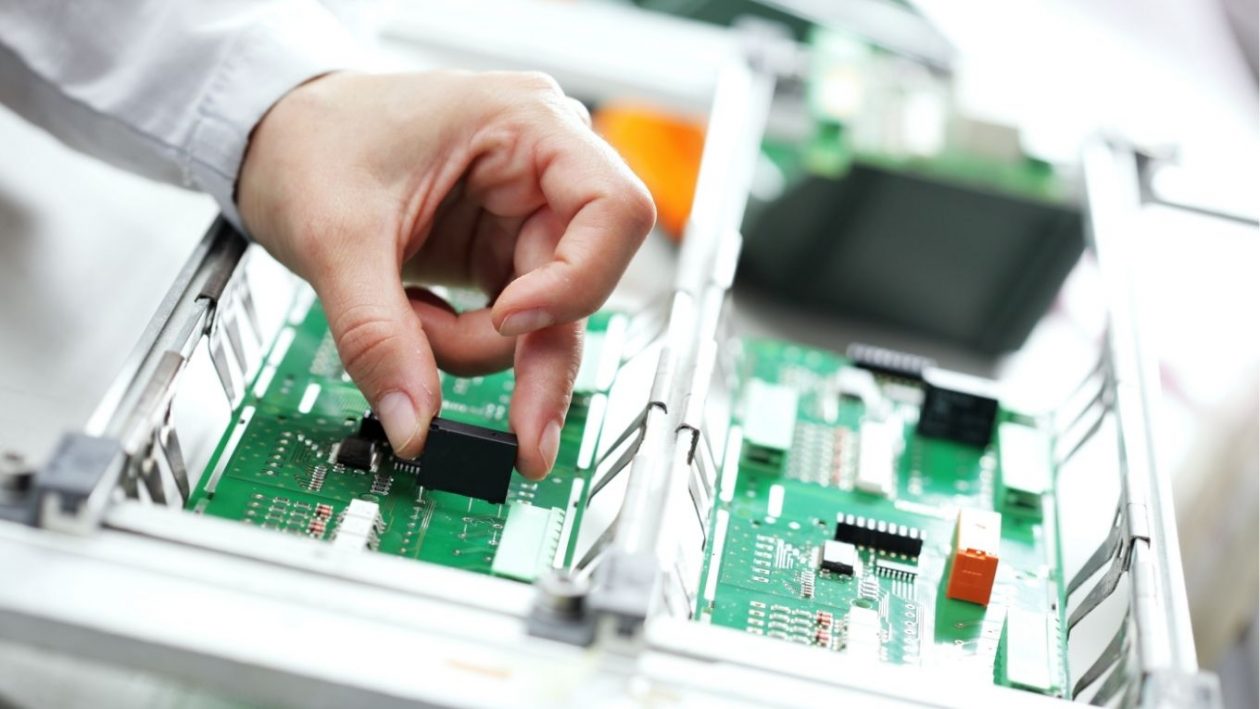

Electronic assembly involves the meticulous process of assembling electronic components into finished products. This detailed guide covers the responsibilities, essential skills, challenges, best practices, and technological advancements in the field of electronic assembly.

Responsibilities of Electronic Assembly Workers

Electronic assembly workers have a variety of duties that ensure the successful completion of electronic products. These responsibilities include:

- Component Assembly: Accurately placing and soldering electronic components onto circuit boards.

- Quality Control: Inspecting assembled products to ensure they meet specified standards and performance criteria.

- Troubleshooting: Identifying and resolving any issues or defects in the assembly process.

- Documentation: Maintaining detailed records of assembly processes, including any modifications or repairs.

- Equipment Maintenance: Performing routine maintenance on assembly equipment to ensure optimal performance.

Essential Skills and Qualifications

Electronic assembly workers need a blend of technical skills, precision, and knowledge to perform their tasks effectively:

Technical Skills

- Soldering: Proficiency in soldering techniques for securing components to circuit boards.

- Reading Schematics: Ability to read and interpret electronic schematics and diagrams.

- Hand-Eye Coordination: Excellent hand-eye coordination for handling small components and tools.

Attention to Detail

- Precision: Ensuring each component is placed accurately to avoid assembly errors.

- Thorough Inspection: Conducting thorough inspections to identify and correct any defects.

Problem-Solving Skills

- Troubleshooting: Diagnosing and fixing issues that arise during the assembly process.

- Adaptability: Adjusting to different assembly techniques and processes as needed.

Challenges in Electronic Assembly

Electronic assembly workers face several challenges that require careful management to ensure quality and efficiency:

- Precision: Maintaining high precision with small components and complex assemblies.

- Quality Control: Ensuring all products meet stringent quality standards and specifications.

- Technology Changes: Keeping up with rapidly evolving electronic technologies and assembly techniques.

- Work Environment: Managing repetitive tasks in a controlled environment, which can lead to physical strain.

Best Practices for Electronic Assembly

Following best practices is essential for maintaining high standards in electronic assembly. Key practices include:

Proper Training and Certification

- Comprehensive Training: Providing thorough training on assembly techniques, equipment use, and safety protocols.

- Certification: Ensuring workers are certified in relevant assembly standards and practices.

Quality Assurance Processes

- Regular Inspections: Conducting frequent inspections at various stages of the assembly process.

- Standardized Procedures: Implementing standardized procedures to ensure consistency and quality.

Ergonomic Workstations

- Ergonomic Design: Designing workstations to reduce physical strain and improve efficiency.

- Adjustable Equipment: Providing adjustable equipment to accommodate different worker needs.

Technological Advancements in Electronic Assembly

Technological advancements have significantly improved the efficiency and precision of electronic assembly:

Automated Assembly Systems

- Robotic Assembly: Utilizing robotic systems for precise and consistent assembly tasks.

- Pick-and-Place Machines: Implementing automated machines to place components accurately on circuit boards.

Advanced Inspection Techniques

- Optical Inspection: Using optical inspection systems to identify defects and ensure quality.

- X-ray Inspection: Employing X-ray technology to inspect hidden connections and components.

Surface Mount Technology (SMT)

- SMT Advantages: Enhancing assembly speed and accuracy with surface mount technology.

- SMT Equipment: Using specialized SMT equipment for placing and soldering components.

Conclusion

Electronic assembly is a critical component of the electronics industry, requiring precision, skill, and adherence to best practices. By staying updated with technological advancements and maintaining high standards of quality, electronic assembly workers can ensure the production of reliable and efficient electronic products.